Lasers & Optical Fibers Technologies

Lasers & Optical Fibers Technologies

Sensors for large smart composite footbridge (DECID2) / Project examples

Collaborative project DECID2: IDIL Fibres Optiques has collaborated with IFSTTAR in order to integrate optical fiber sensors (FBGs) into concrete within the framework of civil engineering applications.

Sensors for large smart composite footbridge (DECID2) summary

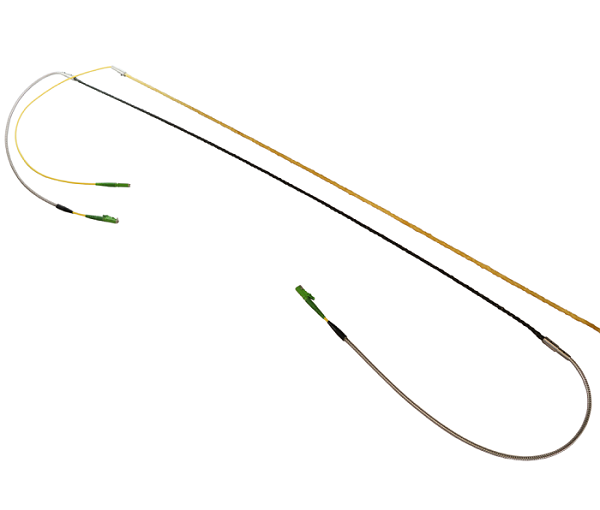

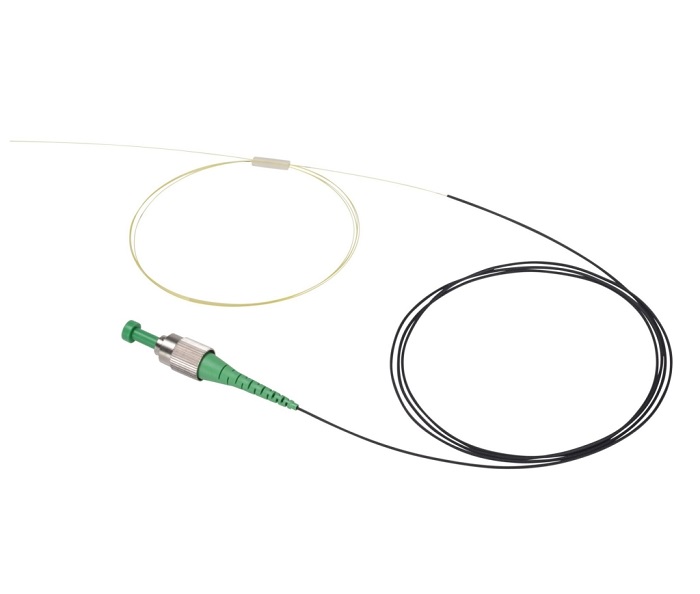

IDIL has developped 176 Fiber Bragg Gratings (FBGs) sensors photo-imprinted on 24 connectorized optical fibers.

Those optical fibers were designed to withstand alkaline metal while resins with a special reticulation process were used. Consequently, the manufactured cable is flexible enough to be packaged in strand and to follow the geometry of the structure that must be monitored.

This particulat shape enables to ensure a continuous and efficient fixation into concrete. Otherwise, this specific coating which consists of a semi-stiff cable allows a perfect information transfer from the concrete as far as the optical fiber without any change in the deformation field.

Contact us

for more informations

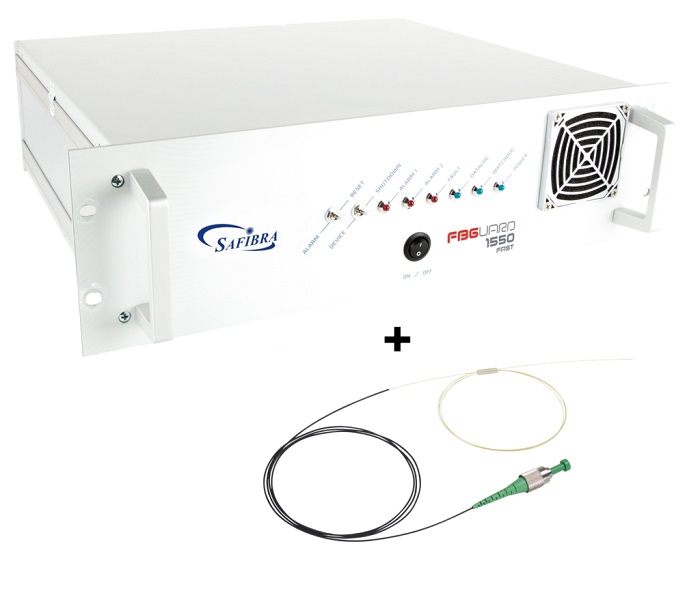

- Fiber Bragg Gratings sensors

- Flexible cable to follow the geometry of the structure

- Optical Time Domain Reflectometry (OTDR)

- Optical Frequency Domain Reflectometry (OFDR)

- Brillouin or Raman frequency interval measurements

- Civil engineering

- Aerospace engineering

- Offshore environment

| DECID2 PROJECT | |

|---|---|

| Period | 2008-2012 |

| Research Institute Collaboration | French Institute of Science and Technology for Transport, Development and |

| Networks (IFSTTAR) | |

| Objective | Demonstartors made out of smart composites with double-capacity of |

| structural health monitoring in-situ by both optical fiber sensors and ultrasonic | |

| patchs | |

| Footbridge dimensions | 20 m long x 7 m large |

| Composition | Pultruded composites: glass fiber/vinylester and carbon/epoxy |

| IDIL Objectives | Integration of fiber optic sensors embedded in a beam of the footbridge by |

| pultrusion | |

| Sensors types | Strain, temperature, vibration |

| Number of sensors | 176 FBG sensors |

| Composition | Glass fiber, epoxy resin |

| Optical fiber | Single mode 1.5 µm SMF 28 (G 652 standard) |

| Number of fibers | 6 fibers per beam (24 fibers in total) |

| Length | 10 cm ≤ L ≤ 50 m |

| Outer diameter | 80 µm fiber |

| Connector type | FC/APC |

| Number of connectors | 48 connectors |

| Metallic jacket diameter | 4.6 mm. The length must be specified. |

| Number fo beams | 4 beams |

| Transfer coefficient | >0,9 |

| Thermal expansion coefficient | 2.2 10-6 °C |

| Strength resistance | 480 MPa |

| Elastic elongation | 3% |

Download Ifsttar press release (French)

The DECID2 project involved the construction of a Platform of large dimensions made entirely of smart composites. Two demonstrators were manufactured and installed.

The target is to experiment and model their performances under mechanical and environmental aging.

Project financed by the single interministerial funds of the DGCIS, the Pays de la Loire, Brittany and Picardy regions to the tune of 2 million euros for an overall budget of 3.5 million euros. The project brings together the following partners: ETPO, DFC, IDIL Fibres Optiques, IXFIBER, Synervia and Cetim as well as the Larmaur laboratories of the University of Rennes 1, GeM of the University of Nantes and the Central School of Nantes and Ifsttar.