Lasers & Optical Fibers Technologies

Lasers & Optical Fibers Technologies

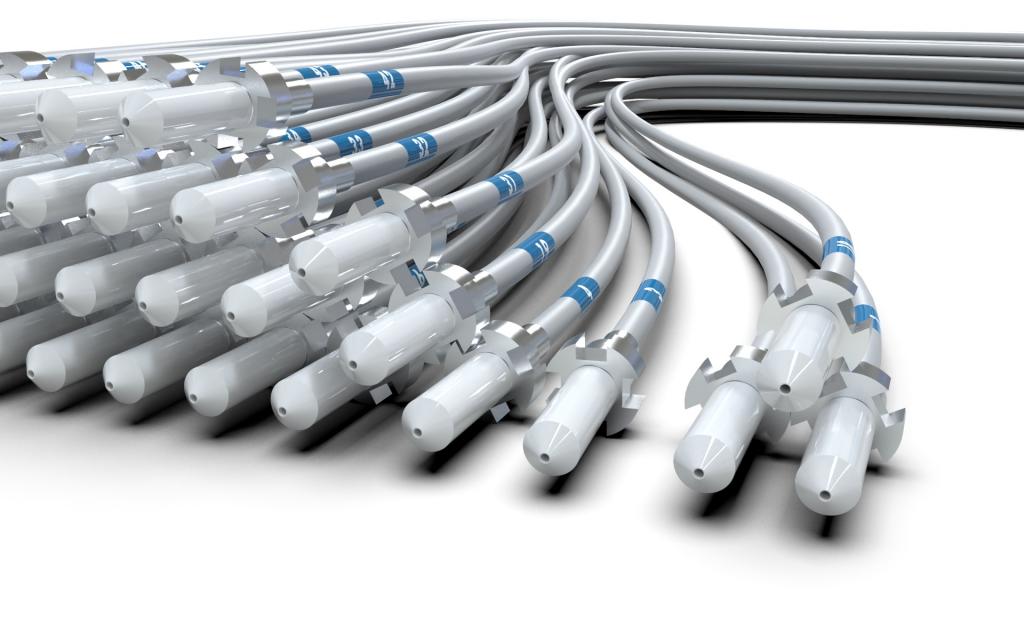

Optical bundle / Bundles & Fiber assemblies

IDIL Fibres Optiques proposes a wide range of tailor-made optical bundles, namely assemblies of multiple optical fibers.

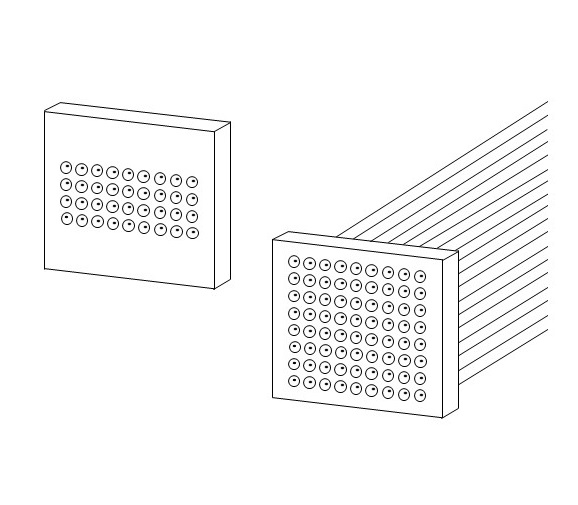

Output termination

In this example, 70 optical fibers are randomly maintained in a SMA connector.

Input termination

In this example, 70 optical fibers are randomly maintained in a capillary (aluminium cannula).

Legs

In this example, 49 optical fibers are put in 49 ceramic ferrules.

Common termination

In this example, 49 optical fibers are placed in a fiber array (7x7 fibers). Thanks to this component, each optical fiber is placed at equal distance (pitch).

Legs

In this example, 7 optical fibers are furcated in 2 connectors :

- 1 fiber in a SMA connector

- 6 fibers, in line in a SMA connector

Common termination

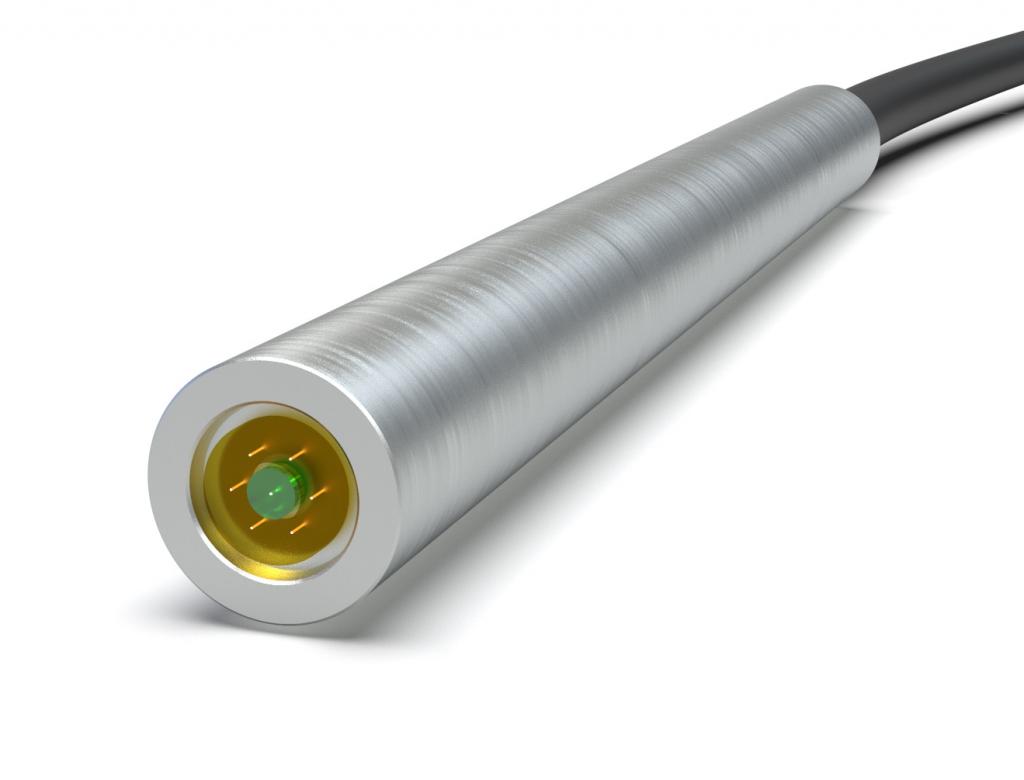

In this example, 7 optical fibers are placed in a probe (1 central fiber and 6 fibers placed in a ring).

A 535 nm high pass filter is added at the end of the probe.

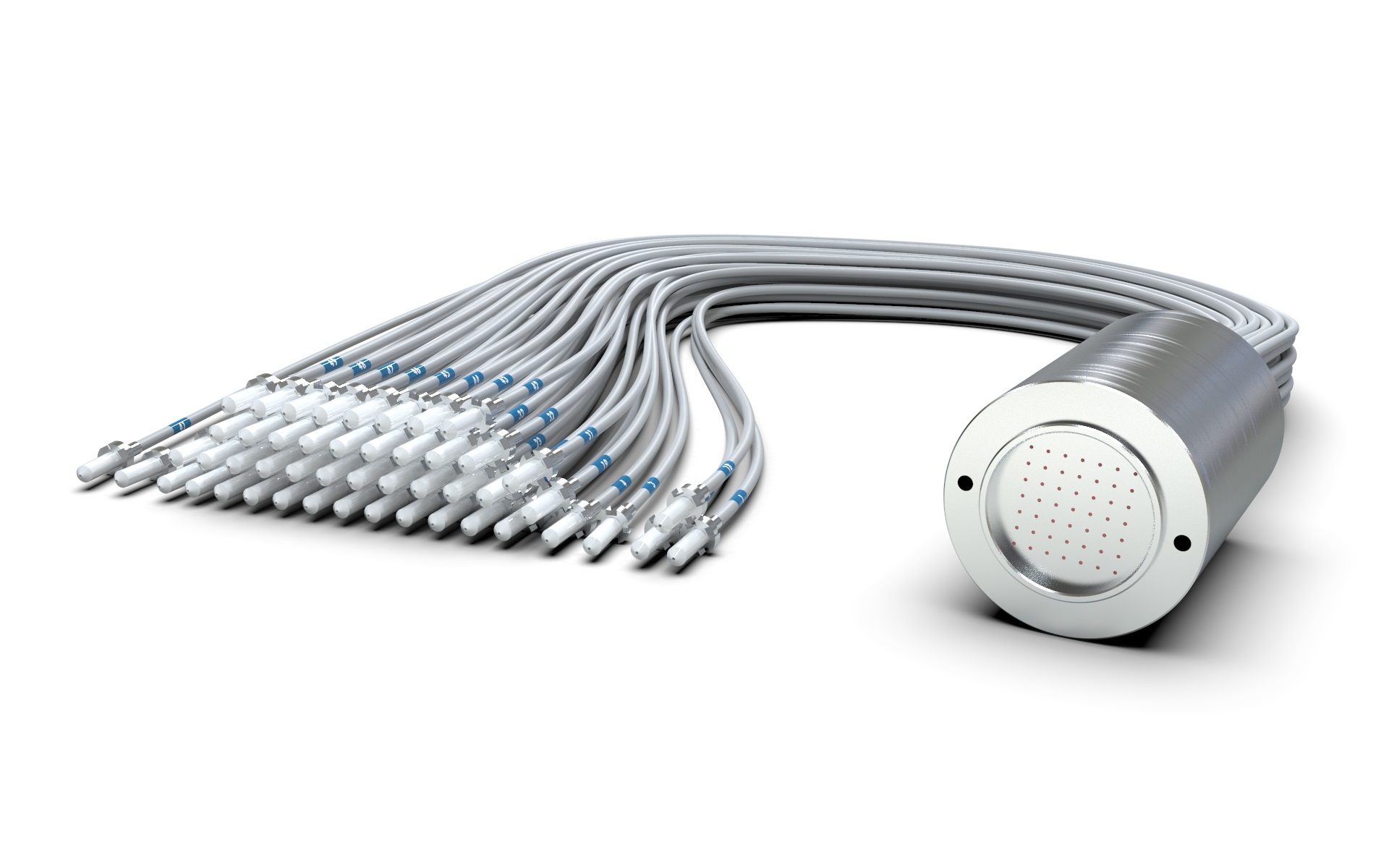

Output termination

In this example, optical fibers are furcated in 4 connectors:

- 19 fibers (2 fiber types) randomly placed in a connector SMA (UV-Vis-NIR light source)

- 4 fibers placed in line in a connector SMA (NIR spectrometer)

- 2 fibers randomly placed in a connector SMA (Vis spectrometer)

- 6 fibers randomly placed in a connector SMA (For fluorescence measurement)

Input termination

In this example, 19 optical fibers are placed in a probe (with a precise fiber positionning given by our customer)

Select your configuration

-

Straight

-

Fan-Out

-

Simple Furcation

-

Complex Furcation

Straight

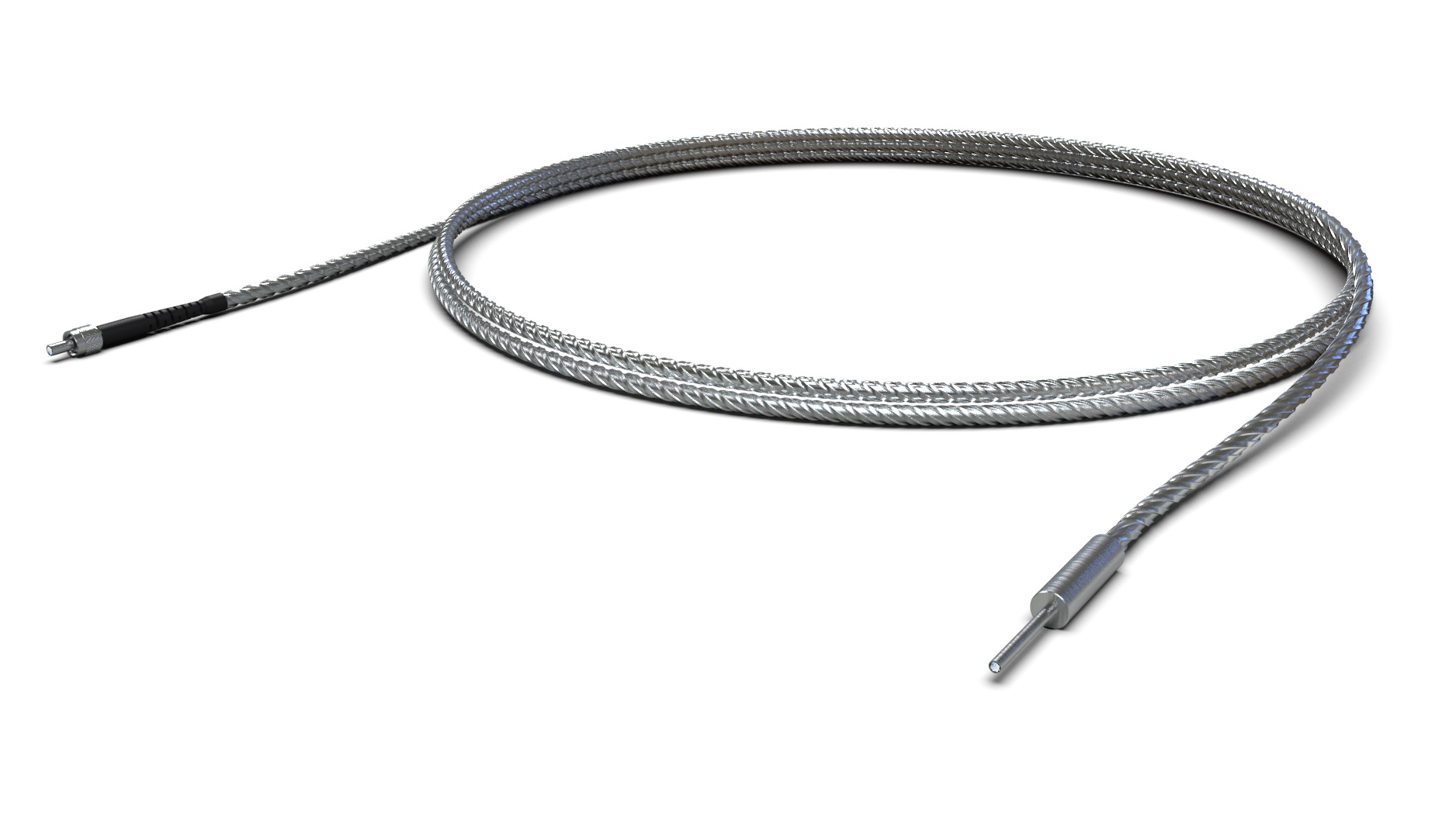

Multiple optical fibers are held together at one end (the input termination). The same fibers are found at the other end (the output termination). Use our NEW configurator tool to customize your straight optical bundle: fiber types, materials and diameters, connectors types, customized ferrules, wavelength, numerical apertures, etc.

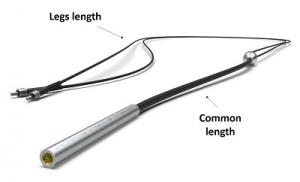

Fan-Out

Multiple optical fibers are held together at one end (the common termination). All fibers are then divided into different legs at the other end. A single fiber is placed in each output leg. Use our NEW configurator tool to customize your fan-out optical bundle: fiber types, materials and diameters, connectors types, customized ferrules, wavelength, numerical apertures, etc.

Simple Furcation

Multiple optical fibers are held together at one end (the common termination). Fibers are then furcated into different legs at the other end. One or multiple fibers can be connectorized in each leg following your specifications. Use our NEW configurator tool to customize your simple furcation optical bundle: fiber types, materials and diameters, connectors types, customized ferrules, wavelength, numerical apertures, etc.

Complex Furcation

IDIL designs complex multi-legs optical bundles. To make it easy, use our online configurator to send us your drawing!

Contact us

for more informations

Configure & get your quote

13

15

29

18

Optical bundle summary

IDIL Fibres Optiques provides custom fiber optic bundles in accordance with customer’s requirements: fiber types, materials and diameters, quantities (from small batch to several hundred), connectors types, customized ferrules, wavelength, numerical apertures, etc.

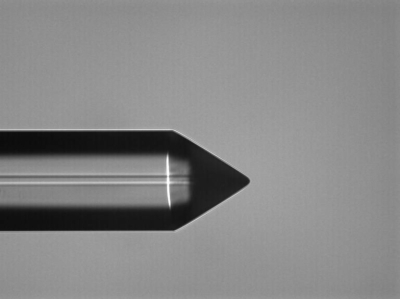

Our engineering flexibility also concerns mechanics and assembling. Actually, Fibers assembling process can be realized without glue which enables to resist a very high power laser (> 1 watt). Otherwise, specific lenses can be put in front of such assemblies.

IDIL Fibres Optiques also produces multi-branch assemblies where fibers are held together on the one end and divided into several branches on the other hand. Positioning of each optical fiber within branches can be precisely determined and implemented in order to meet the required distribution at the end.

Bundle family

Straight bundles

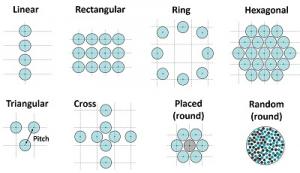

Straight bundles include one input and output. However, they could be not as basic at they seem. Indeed in this configuration, bundles can take a large number of geometries with linear, hexagonal, round, array disposal etc. We can address each fiber independent of I/O disposal. Main applications would be illumination and excitation bundles, endoscopy, imaging systems, optical power transportation or mere offset systems for spectroscopy signal collection. Regarding the number of fiber and your application we will set an optical connector, a capillary or a more complex mechanical device.

Fan-out bundles

Fan-out bundles have to be seen like a common junction split from two to numerous legs. Each leg will contain one fiber and is customizable. Common junction is also of course designed regarding your specification. On your side, the use of this kind of bundle is multiple: gathering light sources for illumination or laser pumping, multiple coupled detectors, sample cartography

Simple and complex furcation bundles

The main difference between Fan-Out and Furcation bundles resides in the fact that you can set as many fiber as you want in each leg. This makes the difference for reflection, fluorescence, backscattering or Raman measurements where you need to illuminate and collect independently. For this purpose we can add filters, lenses or other terminations.

- Custom optical bundles

- Single or multi-branch

- Greater flexibility

- High position precision

- Spectroscopy

- Sensors & Probes

- High power source

- Laser delivery

- Mono-chromators

- Reflective sensors

- Colorimetry

- Pyrometry

- Fluorescence

- Illumination

- Chemical analysis

| CUSTOM | |

|---|---|

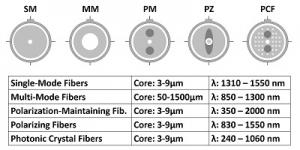

| Fiber type | UV, IR, visible or custom |

| Core diameter | 100 µm, 200 µm, 400 µm or custom |

| Fiber bundle length | Upon request |

| Wavelength | From 180 nm to 5500 nm |

| Numerical apertures | From 0.10 to 0.66 |

| Dimensions | According to the type and the number of fibers |

| Connectors | FC, LC, SC, SMA, ST, MU, E2000, other |

| Patchords | Bare fibers, 900 µm protection, 2.8 mm, others |

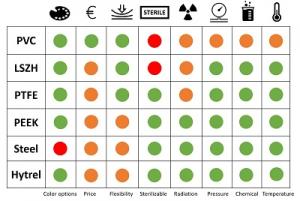

| Fiber material | All-silica, plastic-clad silica, borosilicate glass, fluoride, all plastic materials |

| Configurations | Straight, bifurcated (Y-cable), fan-out configurations, round or linear bundle |

| end configurations | |

A fiber bundle is the assembly of multiple optical fibers. The fibers of the bundle are usually held together at one end, and may be separated into multiple branches at the other end. Fiber bundles provide significantly more light throughout compared to a single optical fiber in a patchcord. They also offer greater physical flexibility and high precision.